Company profile

The history of UAB “Krekenavos agrofirma” spans more than three decades. In 1993, the pig farming complex established in the town of Krekenava was the largest in the country. At that time, a meat processing workshop was built, and the production of meat products began. Over the following decade, as demand for “Krekenavos” products grew significantly, a new facility became necessary as the old one could no longer keep up. Therefore, in 2004, following an investment of more than 23 million euros, a modern, entirely new meat processing plant was built in the Kėdainiai district. Under the roof of the company’s buildings, covering an area of more than 22,000 m², the largest pig and cattle slaughterhouse in Lithuania was established, along with meat cutting and packaging workshops and a thermally processed meat products production unit.

As the company began to focus more on the meat processing business, the “Krekenavos” pig farming complex was sold to the Danish company “Saerimner” in 2008. In the spring of 2009, a new extension was built at the processing plant near Kėdainiai, housing a modern fresh meat packaging workshop. An investment of more than 6 million euros increased the company’s competitiveness both in Lithuania and abroad. Today, we are an EU-standard meat processing company that is constantly growing, improving, and investing not only in new production technologies and equipment but also systematically developing the competencies of our employees. Since 2017, the annual turnover of UAB “Krekenavos agrofirma” has consistently exceeded 120 million euros.

Key Facts

- One of the largest meat processing companies in the Baltic States, with almost 30 years of experience.

- More than 100 tonnes of fresh meat and almost 30 tonnes of meat products are sold every day (including all public holidays).

- The company has a market share of ~30% in fresh meat and ~14% in meat products in Lithuania.

- The company currently employs more than 1,000 employees.

- All products are continuously checked in the quality department to ensure that only products that meet the highest standards reach the shelves of the stores.

- The company’s technologists develop existing products and create new ones to continue to delight our consumers.

Export

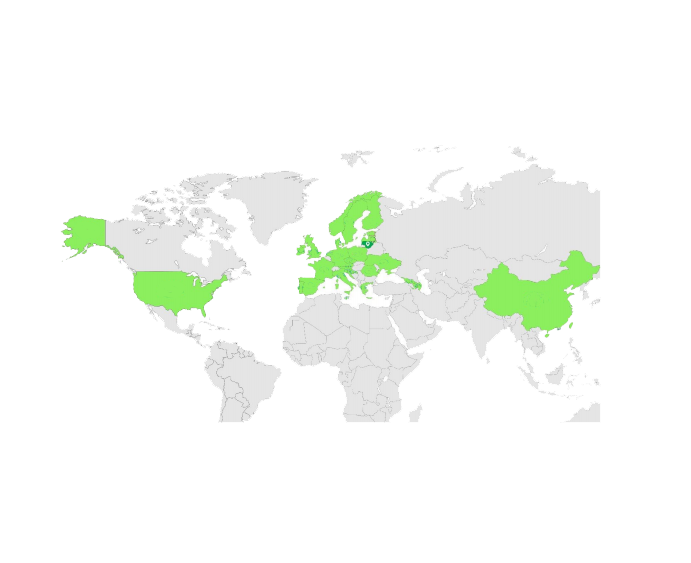

- ~30% of our total production is exported.

- Every year, we export ~12,000 tons of fresh meat and nearly 2,000 tons of meat products.

- Our products reach as many as 32 countries worldwide.

Frequently Asked Questions

In the Media

Good News for Meat Product Consumers

Štai šio straipsnio vertimai į anglų, lenkų ir rusų kalbas. Tekstuose išlaikyta jūsų pateikta HTML ...

Mouth-watering pulled meat: perfect for both lunch and dinner

How to quickly prepare a salad or delicious crepes with meat filling if beef or ...

You Can Never Have Too Many Reflectors

Krekenavos Agrofirma, a meat product company in the Kėdainiai district, produced and distributed 5,000 reflectors. ...